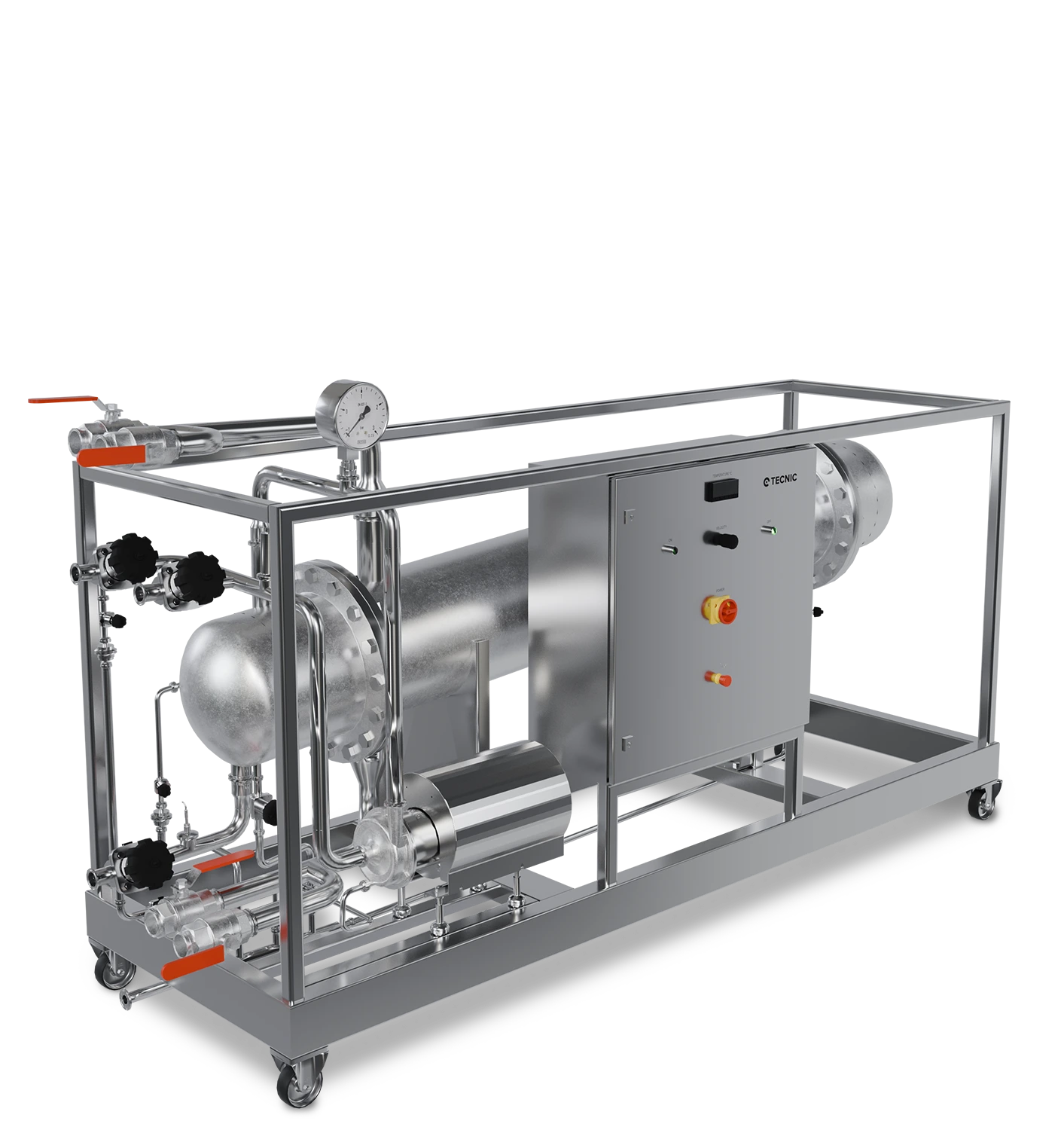

Discover how eLAB TFF Single Use revolutionises perfusion and intensification of biotechnological processes. Optimise your bioprocesses with our effective and proven tool, improving productivity and efficiency in your lab. Designed to ensure gentle cell handling and consistent performance, eLAB TFF enables seamless scale-up from research to production. Its modular design and ease of use make it the ideal solution for laboratories aiming to enhance process control while reducing operational complexity and costs.

Perfusion and Process Intensification with eLAB TFF SU

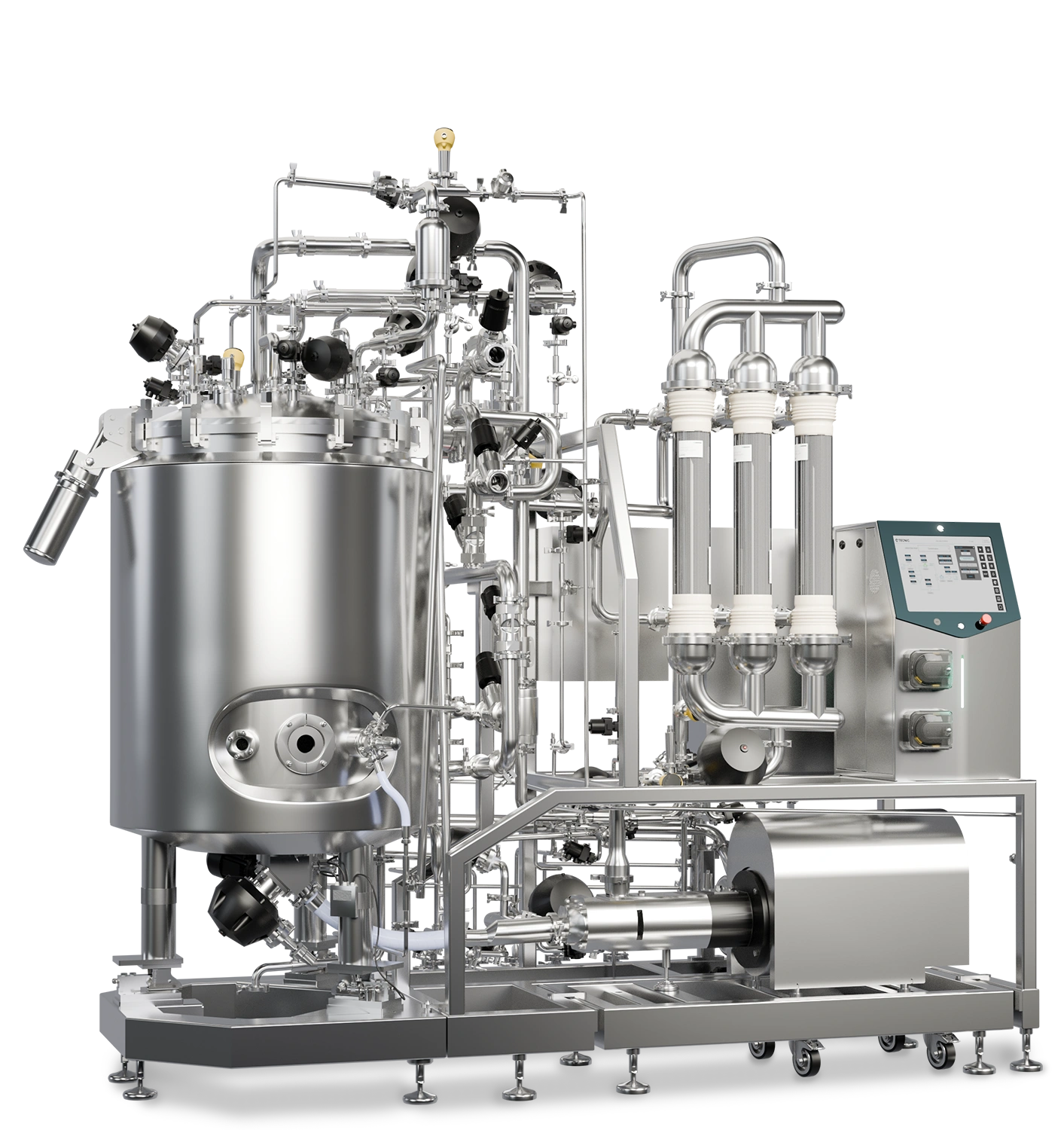

At TECNIC, we are proud to have our exceptional eLAB TFF Single Use ⇀ equipment. This lab equipment is transforming the way we intensify our biotechnological processes, boosting productivity and efficiency in our bioprocesses.

One of the most prominent examples of how eLAB TFF Single Use transforms our processes is through perfusion, a method of continuous culture intensification. In this method, cells are retained in or returned to the bioreactor, allowing higher product yields and higher cell concentrations to be obtained. This approach, which we have refined over time, also helps to reduce the workload and allows the exchange for a fresh medium that provides all the nutrients necessary for the proper maintenance of the cells. This is the value we have always offered at TECNIC: innovative and efficient solutions in biotechnology.

Innovation in process intensification eLAB TFF

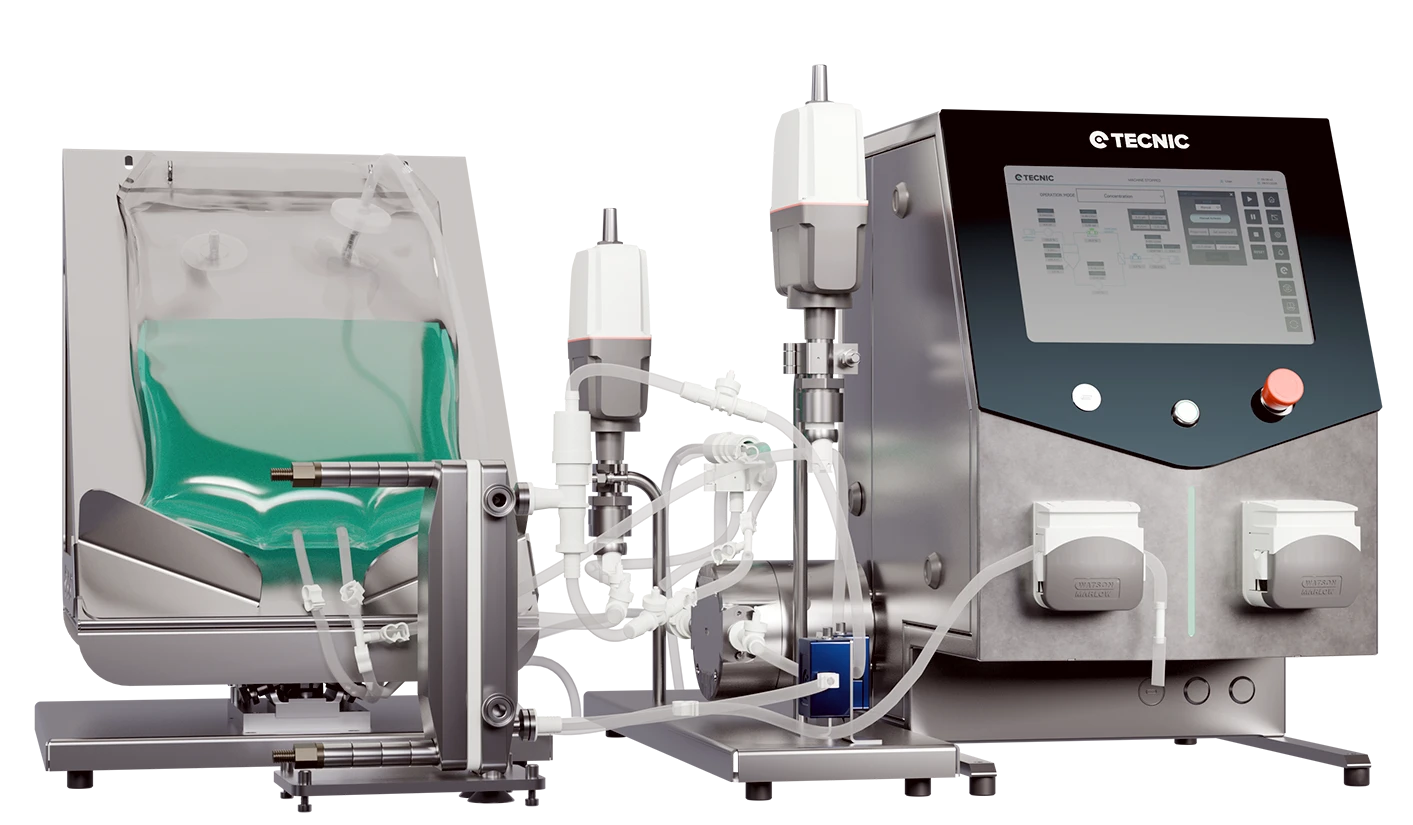

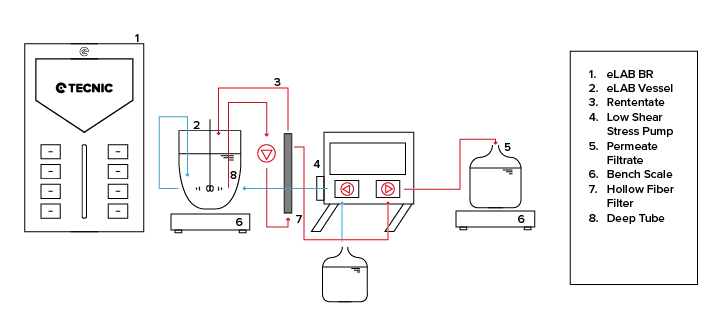

At TECNIC, we choose to use our tangential filtration equipment with hollow fibre style filter technology and a low cell stress recirculation pump. This combination of cutting-edge technologies allows us to obtain high-density cell cultures while minimising the impact on cell viability and optimising the results of our bioprocesses.

Within our eLAB Bioreactor ⇀ equipment, one of the ports is specially designed for perfusion. From this port, the low cell stress pump is connected, which sends the product to the hollow fibre filter. The cells retained in the filter are returned to the bioreactor, where a high cell density culture is obtained. The product filtered through the hollow fibre is connected to one of our integrated peristaltic pumps, allowing precise control of the constant flow of permeate, which is directed to a storage vessel.

The addition of fresh medium into the bioreactor is done via the overflow pump of the eLAB TFF unit, which is controlled based on the weight of the bioreactor. As the permeate is removed, fresh medium is added to maintain a constant weight in the bioreactor. In addition, our standard equipment has two integrated peristaltic pumps, one variable speed and one fixed speed, to control permeate flow and media addition.

At TECNIC, we are committed to excellence and innovation in the biotechnology industry. eLAB TFF Single Use represents our commitment to offer advanced solutions that optimise our bioprocesses and help us reach new levels of productivity and quality.

Do not miss the opportunity to improve your bioprocesses with eLAB TFF Single Use. Contact us for more information and to find out how our solution can benefit your biotech production.

Conclusion

Incorporating perfusion and intensification strategies into bioprocesses is no longer an option but a necessity for biotech companies seeking efficiency, scalability, and consistent product quality. TECNIC’s eLAB TFF solutions are designed to meet these demands, offering robust performance with user-friendly operation. By optimizing media exchange, reducing shear stress, and improving cell viability, our technologies support continuous biomanufacturing processes while minimizing operational costs.

Furthermore, the ability to implement modular systems allows companies to adapt to evolving production needs without overhauling existing infrastructure. This flexibility is key in an industry where time-to-market and regulatory compliance are critical. TECNIC’s expertise ensures seamless integration of perfusion systems, enhancing process control and reducing variability. Our commitment to innovation translates into practical benefits for R&D teams and large-scale manufacturers alike, driving progress in a highly competitive sector.

Contact us to learn how perfusion and intensification can transform your bioprocess efficiency.